|

Tis the season for conferences and expo’s---- They are a great way to network, meet new potential clients, see a new place, and spread your company name. However, if you have ever been a vendor on the other side of the table at these conferences you know that not everyone who comes up to your booth is there to learn more about you company. In the name of entertainment, we have made this short and sweet eccentric people expo guide of the four types of people that you will run into at conferences and how to manage them. 1. Chatty Cathy This close talking conversation enthusiast can either help make a conference memorable or make your life horrible. Chatty Cathy comes in all forms, shapes, and sizes from the “let me tell you a story” guy, to “you remind me of so-and-so” person, to the “I like your shirts” randomness and many more. The whole risk comes from eye contact and a smile. This person is just looking for a nice person to help pass the time and you are that victim. If you are having a slow day, Chatty Cathy helps pass the time and is wonderful, making you laugh, and giving you something to remember. If things are busy though, you are possibly missing out on whoever it is you really want to talk to. The key to managing this eccentric person is making sure you can gauge your flow of other people and know what the agenda is for the conference. If it is a break time or coming close to one you need to help shed this chatty character. If not, enjoy the story, pull up a seat, or get a coffee. 2. Freebie Freddy Pretty self-explanatory, Freebie Fred only wants to know what merch you have for him. They come in, swoop by close enough to see if it is cool, flashy, or if it’s just simply for the taking and will slide it right into their goodie bag. You can typically spot Freddie a mile away, their bag is already full, they are wearing all the gear from previous booths and they also are immediately eyeing your table not you or your marketing material. Best thing if you actually are just giving some things away is to quickly direct them to something you want to provide and keep them moving. If you want, try to say hello or get your 30 second commercial in, but know you won’t get far so don’t take it personal. 3. The "I'm Not The Guy" Guy There are quite a few “I like it, but I’m not the guy” Guys who want to help but simply don’t have the buying power in their company to purchase your product. The key to these eccentric expo people is picking their brain. These well-meaning, non-decision makers can be your champion throughout the process and if you stay on their team, they will support you, talk about you, and be the voices for some of the new products and uses for your company. As they express extreme interest pick their brain on finding out what the typical process for decisions is for their company, who are the decision makers, what they like and don’t like and how you can work with “I’m not the guy” guy to change the company for the better. Keep in touch with them, offer to buy them coffee or lunch and keep them engaged and happy and it will be worth your while, but remember don’t go too extreme, because they are not “the guy”. 4. The Unicorn The interested future customer that has the buying power is the whole reason you are at the conference. If you can find them or realize you have one don’t let it go. Keep them engaged, find their interest, timeline and pain and how you can address their needs. Make sure you find out what else they are looking for, be a resource to them and yes do not forget to get their information and set up a follow up. You are a pro, don’t get mesmerized by the unicorn and forget to take a picture. Now, I know that this is silly and pokes fun at people, but on a more serious note, we love going to conferences and are happy to see anyone who is willing to come up and say hi, yes, even you Mr.Freebie. I know there are times where I have certainly been all four of these types of people depending on my company and the journey of my career. No matter who you are, you are always welcome to come to the STAC table and talk.

0 Comments

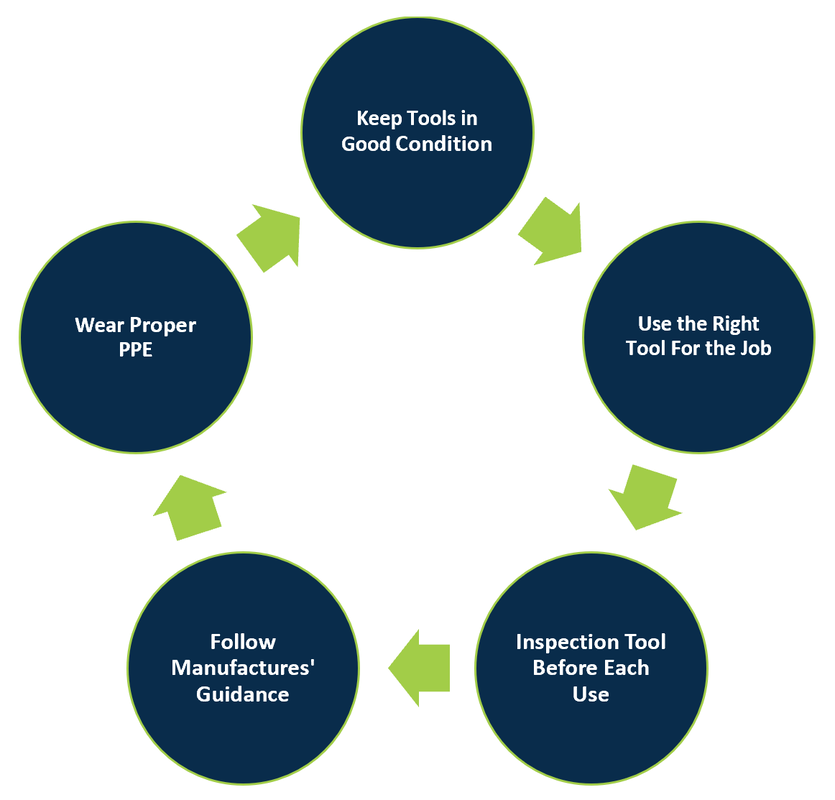

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner Portable Abrasive Tools:

Portable abrasive grinding, cutting, polishing, and wire buffing wheels create special safety problems because they may throw off flying fragments. Abrasive wheel tools must be equipped with guards that: 1) cover the spindle end, nut, and flange projections; (2) maintain proper alignment with the wheel; and (3) do not exceed the strength of the fastenings. Before an abrasive wheel is mounted, it must be inspected closely for damage and should be sound- or ring-tested to ensure that it is free from cracks or defects. To test, wheels should be tapped gently with a light, non-metallic instrument. If the wheels sound cracked or dead, they must not be used because they could fly apart in operation. A stable and undamaged wheel, when tapped, will give a clear metallic tone or “ring.” To prevent an abrasive wheel from cracking, it must fit freely on the spindle. The spindle nut must be tightened enough to hold the wheel in place without distorting the flange. Always follow the manufacturer’s recommendations. Take care to ensure that the spindle speed of the machine will not exceed the maximum operating speed marked on the wheel. An abrasive wheel may disintegrate or explode during start-up. Allow the tool to come up to operating speed prior to grinding or cutting. The employee should never stand in the plane of rotation of the wheel as it accelerates to full operating speed. Portable grinding tools need to be equipped with safety guards to protect workers not only from the moving wheel surface, but also from flying fragments in case of wheel breakage. When using a powered grinder: Always use eye or face protection; Turn off the power when not in use; & Never clamp a hand-held grinder in a vise Guards: The exposed moving parts of power tools need to be safeguarded. Belts, gears, shafts, pulleys, sprockets, spindles, drums, flywheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded. Machine guards, as appropriate, must be provided to protect the operator and others from the following: Point of operation, In-running nip points., Rotating parts, & Flying chips and sparks Safety guards must never be removed when a tool is being used. Portable circular saws having a blade greater than 2 inches (5.08 centimeters) in diameter must be equipped at all times with guards. An upper guard must cover the entire blade of the saw. A retractable lower guard must cover the teeth of the saw, except where it makes contact with the work material. The lower guard must automatically return to the covering position when the tool is withdrawn. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. The Army provides opportunities that a normal civilian would not experience. I’ve been lucky to have a lot of different unique experiences and chances that most people would dream about. I’ve thrown hand grenades, fired machine guns, fired a grenade launcher, performed in war game maneuvers, driven Humvees and the larger trucks, tested my physical limits, and now I can add to that list making a massive explosion. Over the past couple of weeks, I had the opportunity to work side-by-side with an Explosive Ordnance Disposal (EOD) company. It was a chance to break out of the normal routine of the deployment and go to a different base and experience first hand a small portion of what EOD soldiers do. By far the coolest thing was disposing of expired ammo. For hours we help place this ammo into three shot holes. Basically, just a large hole in the ground. We placed all sorts of ammunition to include tank rounds, mortar rounds, AT4s (bazooka), smoke grenades, phosphorus grenades, crater bombs, and C4. Once all the thousands of pounds of ammunition were placed, it was time for EOD to prime the fuses, and back away from the shot holes. Our vantage point was a mile away from the shot holes. We waited in anticipation during the 5-minute delayed time fuse. Finally, all at once there was a simultaneous explosion in all 3 shot holes creating a massive explosion. First was the massive fireball, even at a mile away we could feel the heat from the explosion, about 10 seconds later we heard the sound of the explosion and felt the shockwave. It was truly an awe inspiring and terrifying experience. The explosion created a massive mushroom cloud that ascended hundreds of feet in the air. It was like watching a firework show in which all the fireworks exploded at one time. NOTE: There is offensive language in the video (it is the Army) After the explosion we drove back down to the shot holes are we amazed at how much deeper they got. And there wasn’t a single piece of ammunition to be seen. On the last night before we left, we had a cross training day followed by a grill out. I got the chance to put on the bomb vest (it’s roughly 90 pounds), got to play around with their robots, and got to watch them do their own practical exercises. During the grill out we had a fire, we were just sitting around the fire having a good time. If it wasn’t for the razor wire fences, and the constant sounds of helicopters flying overhead, I would have thought I was back in America. Nights like that truly raise the morale on the deployment. It’s easy to fall into a rut and be negative, I just try to take these small little things to keep the spirits up. Getting care packages, facetiming with family, and getting pictures and videos of my daughter is a constant source of morale. I thankfully have been getting lots of care packages (which I am grateful for) and have over 700 pictures and videos of my daughter on my phone. I will easily have over 1,000 pictures before I leave. It’s still hard to watch her grow from here. But my wife is doing an excellent job at home holding down the fort through the numerous deployment trolls that have come up and raising our daughter. At this point I am almost half way through the deployment and can’t wait to go home after we complete our mission. OSHA Standard: 1926.200 (Subpart G)

Occurrence: Upon Initial Assignment Frequency: As jobsite conditions or roles change Background: According to the Bureau of Labor and Statistics, transportation incidents accounted for 66% of fatal roadway worksite incidents. In most of these occurrences, a worker was hit by a moving vehicle. Incidentally, backing vehicles accounted for 27 of the 48 pedestrian vehicular incidents. 60% of cases involving workers hit by backing vehicles involved dump trucks. Employer Responsibilities: Signs and symbols shall be visible at all times when work is being performed and shall be removed or covered promptly when the hazards no longer exist. Construction areas shall be posted with legible traffic signs at points of hazard. All traffic controls signs or devices used for protection of construction workers shall conform to Part VI of the Manual of Uniform Traffic Control Devices (MUTCD) Danger Signs: Shall be used only where an immediate hazard exists. Danger signs shall have red as the predominating color for the upper panel; black outline on the borders; and a white lower panel for additional sign wording. Caution Signs: Shall be used only to warn against potential hazards or to caution against unsafe practices. Caution signs shall have yellow as the predominating color; black upper panel and borders: yellow lettering of "caution" on the black panel; and the lower yellow panel for additional sign wording. Black lettering shall be used for additional wording. Exit Signs: When required, shall be lettered in legible red letters, not less than 6 inches high, on a white field and the principal stroke of the letters shall be at least three-fourths inch in width. Safety Instruction Signs: When used, shall be white with green upper panel with white letters to convey the principal message. Any additional wording on the sign shall be black letters on the white background. Directional signs. Other than automotive traffic signs shall be white with a black panel and a white directional symbol. Any additional wording on the sign shall be black letters on the white background. Traffic signs: Construction areas shall be posted with legible traffic signs at points of hazard. Accident prevention tags: Accident prevention tags shall be used as a temporary means of warning employees of an existing hazard, such as defective tools, equipment, etc. Summary: Take extra precaution when driving or working in a work zone near roadways. Don’t let outside distraction come into play, there are lives at stake. |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed