|

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background: Five basic safety rules can help prevent hazards associated with the use of hand and power tools: Fuel-powered tools are usually operated with gasoline. The most serious hazard associated with the use of fuel-powered tools comes from fuel vapors that can burn or explode and also give off dangerous exhaust fumes. The worker must be careful to handle, transport, and store gas or fuel only in approved flammable liquid containers, according to proper procedures for flammable liquids.

Before refilling a fuel-powered tool tank, the user must shut down the engine and allow it to cool to prevent accidental ignition of hazardous vapors. When a fuel-powered tool is used inside a closed area, effective ventilation and/or proper respirators such as atmosphere-supplying respirators must be utilized to avoid breathing carbon monoxide. Fire extinguishers must also be available in the area. To prevent hazards associated with the use of liquid fuel tools, workers should observe the following precautions:

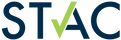

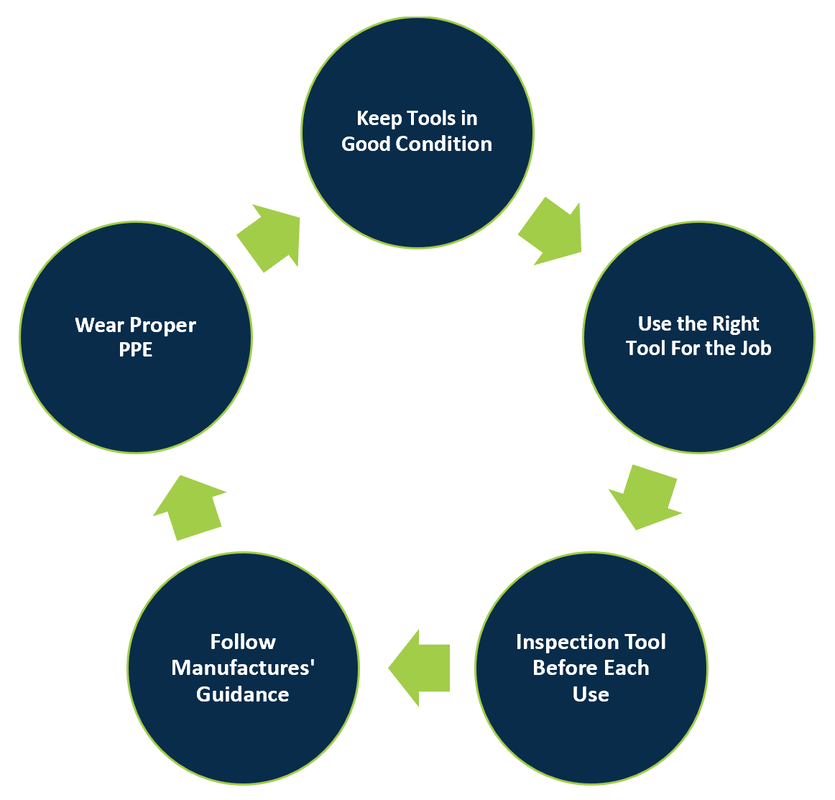

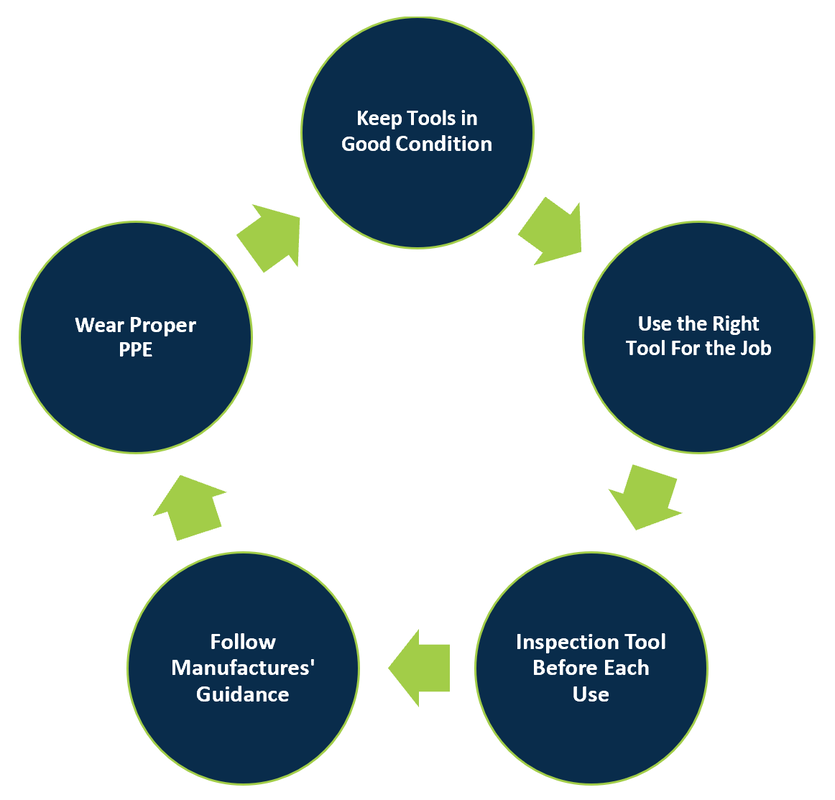

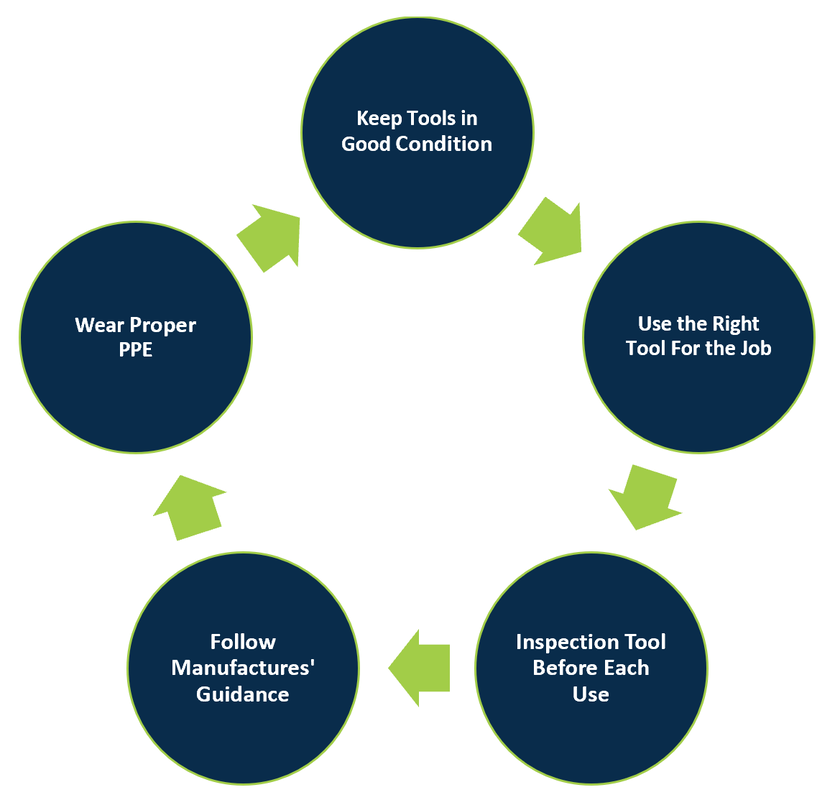

Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Cracked saw blades must be removed from service. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE.

0 Comments

As severe weather month comes to a close it is important to plan how to protect your job site from severe weather. From flooding, to blizzards, to tropical storms, to tornado, to extreme heat, all types of weather impact the productivity and safety to a project. The safety of the team members and risk impact on the project are both critical to the overall success. As we discuss some simple items to prepare your job site, stop and think how your project would be impacted if there was a natural disaster.

1. Have a plan: If you fail to plan, you plan to fail. This is by far the minimum that should be done for every project, plan for the what ifs and the likelihood of a weather event happening relevant to that area. Just having good insurance is not enough for a plan. Insurance may help cover the damage, but it doesn’t cover lost time, the added stress of fixing what has been destroyed, the possibilities that some items aren’t easily replaced (special tools, materials, or equipment that has lead time). A good plan needs to have action items, individuals responsible for those items, and the chain of events to stop work and prepare for the unexpected event. For example, on every project that is expected to have snow throughout the course of the project, there needs to be a plan in the case of a blizzard, and the more likelihood plan of snow removal for the project. There needs to be one individual responsible for arriving early each morning in the event of snow that clears the pathways on the job site to allow access for all other workers. In the less likely case of a blizzard, there must be a responsible weatherman that, at a certain point, will call off work the next day in expectation of the catastrophic event. At the close of work the day prior there should also be protocols for securing and storing important items on the job site. 2. Expect the unexpected: Don’t rely on the notion that it hasn’t happened before, or something was engineered to withstand this type of weather. The patterns of weather today are drastically different than the patterns of the past and on many accounts, we are breaking historical norms. If you are in an area that has a 100-year flood zone, expect to have that 100-year flood during the duration of the project. If you are in an area that is near rivers or waterways, don’t expect the levy to withstand the weather today that was designed 60 years ago for a drastically different time. It isn’t the rain that will impact the project, but the broken levy which allowed the flooding to happen near the area. 3. Own Your Responsibilities: Where most plans fail is the link in communication and accountability. “I thought so and so was taking care of it” or “I didn’t know that was on me” are typical responses after something unexpected has occurred. Something that I saw recently on a project was a large poster which stated, “What do I own” and it had a section for each department and the items they are fundamentally responsible for including the management and the main office. In your plan individual positions need to be identified and therefore individuals held responsible for performing tasks, notifying others, or getting people involved in securing the project. 4. Change Your Plan: This may seem like it doesn’t belong, but it is crucial to a project’s success. No two projects are exactly alike and as people notice or believe there is a better way, the plan itself needs to change and those changes communicated to the other team members. Having a plan that is stagnant and sits on the shelf is a plan that is destined not to be used and eventually forgotten. Unfortunately, severe weather is both unexpected and uncontrollable. Taking the time to stop, think of the possibilities, making a plan and adjusting it seems like a very simple and no-brainer item, but unfortunately most people don’t do it. Those that do, many times become complacent and go through the motions, not adjusting the plan as necessary. Preparing your job for severe weather is not rocket surgery, but it is something that needs to be communicated on all levels and taken seriously in the world we live in today. Be safe and stay moving. I have officially crossed the midway point in the deployment. It is crazy how humans have the ability to cope with their surroundings, and within a short time, find it ordinary and to make a routine that almost seems normal. I know that I have gotten to this point. Home seems almost foreign, it will almost be a culture shock when I do eventually go home.  Back at home in Ohio, the temperature has been below 40 degrees most of winter and has seen lots of rain and snow. I haven’t seen a serious rainstorm since November (although when it did rain, we received the average yearly rainfall of Kuwait in just 8 hours, the base was flooded. But that was a one in a hundred-year rain storm). It does rain, but it mainly sprinkles. And it doesn't rain for very long either.  Snow storms have been replaced by sandstorms, of which we have had 3, but none major. To me, 50-degree weather is freezing. I’ll even wear hoodies and pants when it’s in the upper 50s. I have been lucky enough to have started being here in the winter, the temperature is relatively warm (70s) and sunny during the day and cool at night (40-50s). Sand storms are rather annoying. Unlike snowstorms you have to actually worry about the sand getting in your eyes. You also have to cover your face so no sand gets in your mouth. I'd take a snowstorm over a sandstorm any day. Another difference is the living situation. I lived in a nice house with just my wife and daughter, I also have the luxury of a master bathroom back at home. I now live in a barracks with 35 other males. It is an open barracks, but we have “rooms” separated by the wall lockers, our “doors” are curtains. Most people have tvs, or game system to stay busy at the end of the night. The barrack surprisingly stays relatively quiet and lights are out by 2200 during the week. My barracks does not have running water or internal plumbing. Instead there are bathroom trailers on both side of the barracks complex, of which my complex alone has 45 barracks buildings. The bathroom trailers are alright, just never expect to have a consistently warm shower, just expect a cold shower and savor when you get a warm shower. Another interesting thing, is that some of the portlets have running water. There portlets with the running water are spray painted “western style,” and they have a real toilet and urinal. If you are wondering, yes, they do have an “eastern style” portlet, it literally is a portlet with a hole instead of a toilet. Speaking of water, there is no “potable” running water in my zone. All water that is drinkable is bottled water. I drink anywhere from 6-8 bottles of water a day. Water stations are set up around my zone for soldiers to grab water. It will be odd paying for bottled water when I get home, as it is free and readily available. I still get the chance to Facetime my wife (Julie) and daughter (Jane) 2-3 times a week. Pictures and videos are also my lifeline, of which I now have over 800 of Jane. Being away from my wife and daughter has still been the hardest part about this deployment, the best parts of my day are getting those pictures and videos. And the highlight of my week is getting to facetime them. I know I’ll never take family for granted. I’m blessed to have a great family that messages me regularly and sends me numerous care packages (I have been called the "Care Package King"). It’s crazy how going away 7,000 miles can sometimes bring you closer to people. I know that I feel closer to my family. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power

Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background: Five basic safety rules can help prevent hazards associated with the use of hand and power tools: OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Hand tools are tools that are powered manually. Hand tools include anything from axes to wrenches. The greatest hazards posed by hand tools result from misuse and improper maintenance. Employees who use hand and power tools and are exposed to the hazards of falling, flying, abrasive, and splashing objects, or to harmful dusts, fumes, mists, vapors, or gases must be provided with the appropriate personal protective equipment. Employees should be trained in the proper use of all tools. Workers should be able to recognize the hazards associated with the different types of tools and the safety precautions necessary. Five basic safety rules can help prevent hazards associated with the use of hand and power tools: General Safety:

Wrenches must not be used when jaws are sprung to the point that slippage occurs. Impact tools such as drift pins, wedges, and chisels must be kept free of mushroomed heads. The wooden handles of tools must not be splintered. Iron or steel hand tools may produce sparks that can be an ignition source around flammable substances. Where this hazard exists, spark-resistant tools made of non-ferrous materials should be used where flammable gases, highly volatile liquids, and other explosive substances are stored or used. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Knives and scissors must be sharp; dull tools can cause more hazards than sharp ones. Cracked saw blades must be removed from service. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background:

Employees using electric tools must be aware of several dangers. Among the most serious hazards are electrical burns and shocks. Electrical shocks, which can lead to injuries such as heart failure and burns, are among the major hazards associated with electric powered tools. Under certain conditions, even a small amount of electric current can result in fibrillation of the heart and death. An electric shock also can cause the user to fall off a ladder or other elevated work surface and be injured due to the fall. To protect the user from shock and burns, electric tools must have a three-wire cord with a ground and be plugged into a grounded receptacle, be double insulated, or be powered by a low-voltage isolation transformer. Three-wire cords contain two current carrying conductors and a grounding conductor. Any time an adapter is used to accommodate a two-hole receptacle, the adapter wire must be attached to a known ground. The third prong must never be removed from the plug. Double-insulated tools are available that provide protection against electrical shock without third-wire grounding. On double-insulated tools, an internal layer of protective insulation completely isolates the external housing of the tool. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Employee Requirements: To prevent hazards associated with the use of power tools, workers should observe the following general precautions:

Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed