|

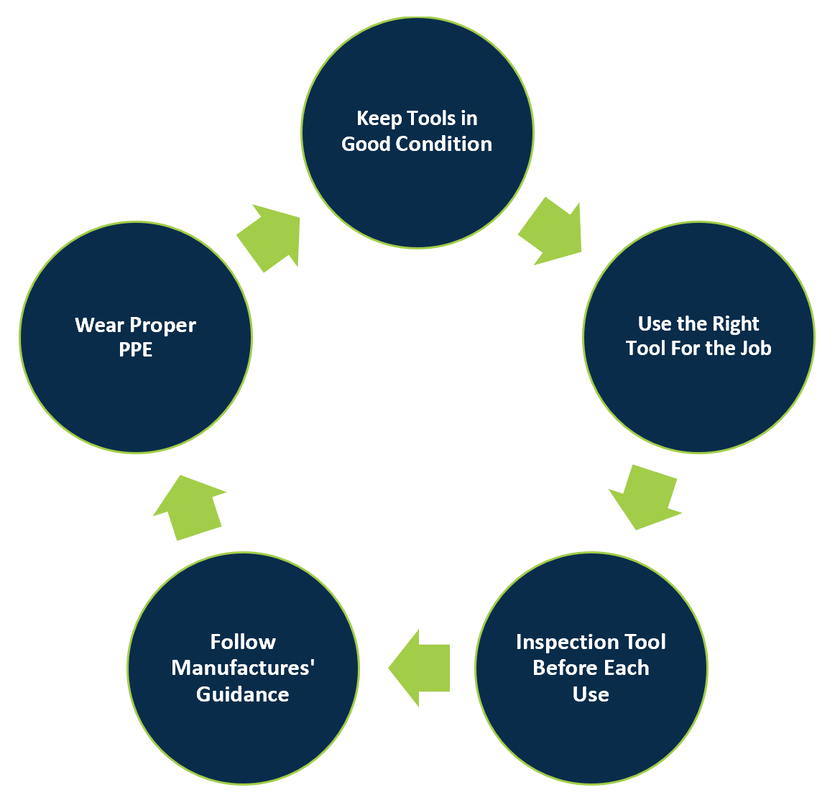

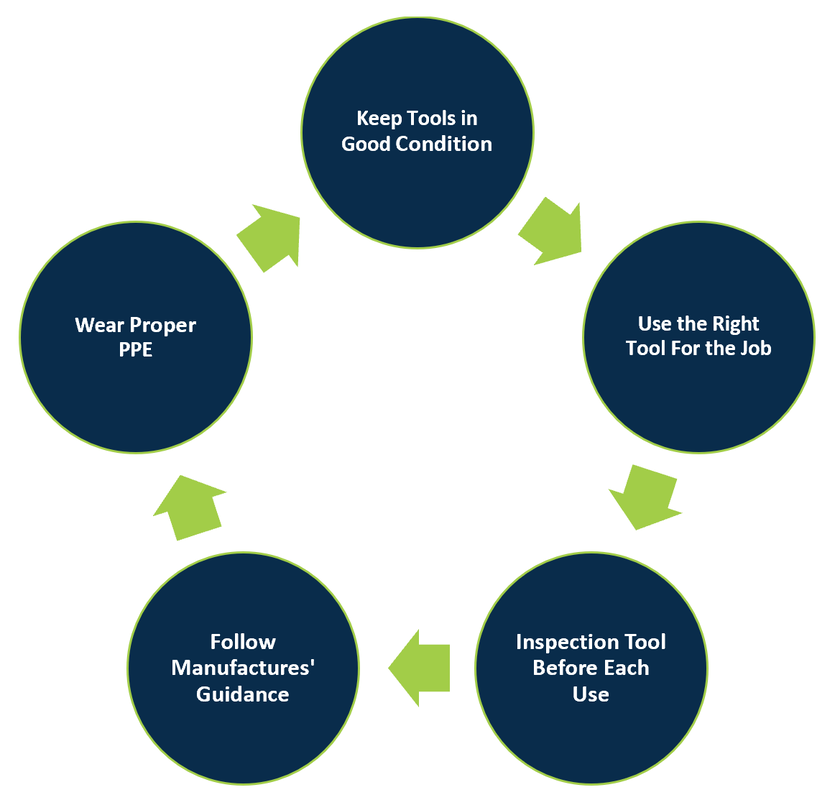

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Hand tools are tools that are powered manually. Hand tools include anything from axes to wrenches. The greatest hazards posed by hand tools result from misuse and improper maintenance. Employees who use hand and power tools and are exposed to the hazards of falling, flying, abrasive, and splashing objects, or to harmful dusts, fumes, mists, vapors, or gases must be provided with the appropriate personal protective equipment. Employees should be trained in the proper use of all tools. Workers should be able to recognize the hazards associated with the different types of tools and the safety precautions necessary. Five basic safety rules can help prevent hazards associated with the use of hand and power tools: General Safety:

Wrenches must not be used when jaws are sprung to the point that slippage occurs. Impact tools such as drift pins, wedges, and chisels must be kept free of mushroomed heads. The wooden handles of tools must not be splintered. Iron or steel hand tools may produce sparks that can be an ignition source around flammable substances. Where this hazard exists, spark-resistant tools made of non-ferrous materials should be used where flammable gases, highly volatile liquids, and other explosive substances are stored or used. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Knives and scissors must be sharp; dull tools can cause more hazards than sharp ones. Cracked saw blades must be removed from service. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE.

0 Comments

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background:

Employees using electric tools must be aware of several dangers. Among the most serious hazards are electrical burns and shocks. Electrical shocks, which can lead to injuries such as heart failure and burns, are among the major hazards associated with electric powered tools. Under certain conditions, even a small amount of electric current can result in fibrillation of the heart and death. An electric shock also can cause the user to fall off a ladder or other elevated work surface and be injured due to the fall. To protect the user from shock and burns, electric tools must have a three-wire cord with a ground and be plugged into a grounded receptacle, be double insulated, or be powered by a low-voltage isolation transformer. Three-wire cords contain two current carrying conductors and a grounding conductor. Any time an adapter is used to accommodate a two-hole receptacle, the adapter wire must be attached to a known ground. The third prong must never be removed from the plug. Double-insulated tools are available that provide protection against electrical shock without third-wire grounding. On double-insulated tools, an internal layer of protective insulation completely isolates the external housing of the tool. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Employee Requirements: To prevent hazards associated with the use of power tools, workers should observe the following general precautions:

Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1910.134 Training Frequency: Upon initial assignment (before mask is worn), and annually. Training Style: Hands-on When is Respiratory Protection Required? - In any workplace where respirators are necessary to protect the health of the employee or whenever respirators are required by the employer Background: Respiratory Protection Program: Respiratory protection program requires the employer to develop and implement a written respiratory protection program with required worksite-specific procedures and elements for required respirator use. The program must be administered by a suitably trained program administrator. In addition, certain program elements may be required for voluntary use to prevent potential hazards associated with the use of the respirator. The program shall be updated as necessary to reflect those changes in workplace conditions that affect respirator use. The employer shall include in the program the following provisions:

The employer shall provide respirators, training, and medical evaluations at no cost to the employee. Training Information: The training must be comprehensive, understandable, and recur annually, and more often if necessary. The employer shall ensure that each employee can demonstrate knowledge of at least the following:

Retraining: Retraining shall be administered annually, and when the following situations occur:

OSHA Standard: 1926.64

Training Requirement: Initial training is required for each employee involved in operating a process of highly hazardous chemicals BEFORE being involved in that operation. Refresher training shall be provided at least every three years, and more often if necessary. Training Documentation: The employer shall prepare a record which contains the identity of the employee, the date of training, and the means used to verify that the employee understood the training. Training: All employees, including maintenance and contractor employees, involved with highly hazardous chemicals need to fully understand the safety and health hazards of the chemicals and processes they work with for the protection of themselves and others. The operating procedures are often viewed as the standard operating practices (SOPs) for operations. Control room personnel and operating staff, in general, need to have a full understanding of operating procedures. Training in subjects such as operating procedures and safety work practices, emergency evacuation and response, safety procedures, routine and nonroutine work authorization activities, and other areas pertinent to process safety and health will need to be covered by an employer’s training program. Because of this this, hands-on-training is strongly encouraged to be used. Training evaluations are strongly encouraged. If, after the evaluation, it appears that the trained employees are not at the level of knowledge and skill that was expected, the employer will need to revise the training program, provide retraining, or provide more frequent refresher training sessions until the deficiency is resolved. Audits: Employers need to select a trained individual or assemble a trained team of people to audit the process safety management system and program. The audit is to include an evaluation of the design and effectiveness of the process safety management system and a field inspection of the safety and health conditions and practices to verify that the employer’s systems are effectively implemented. Evaluate: Employers need to periodically evaluate their training programs to see if the necessary skills, knowledge, and routines are being properly understood and implemented by their trained employees. Subpart: D – Occupational Health and Environmental Controls

OSHA Standard: 1926.59/1910.1200 Occurrence: Initially upon assignment. Frequency: As chemicals, conditions or roles change. Training Style: Hands on training, toolbox talk, classroom instruction. Background: The purpose of this section is to ensure that the hazards of all chemicals produced or imported are classified, and that information concerning the classified hazards is transmitted to employers and employees. This standard is to be consistent with the provisions of the United Nations Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Revision 3. The transmittal of information is to be accomplished by means of comprehensive hazard communication programs, which are to include container labeling and other forms of warning, safety data sheets and employee training. Employer Responsibilities: Employers are required to provide employees with effective information and training on hazardous chemicals in their work area at the time of their initial assignment, and whenever a new chemical hazard the employees have not previously been trained about is introduced into their work area. Employees shall be informed of:

Employee training shall include at least:

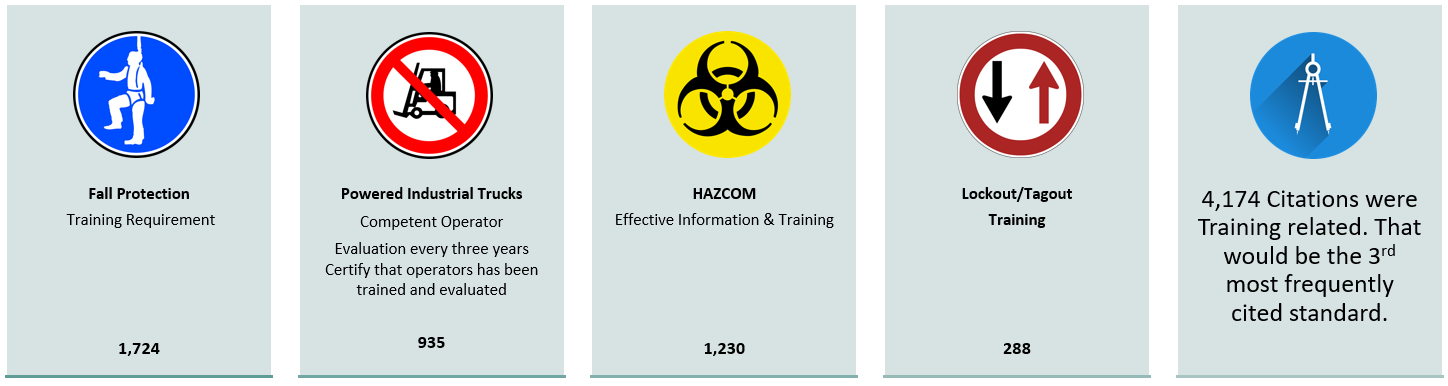

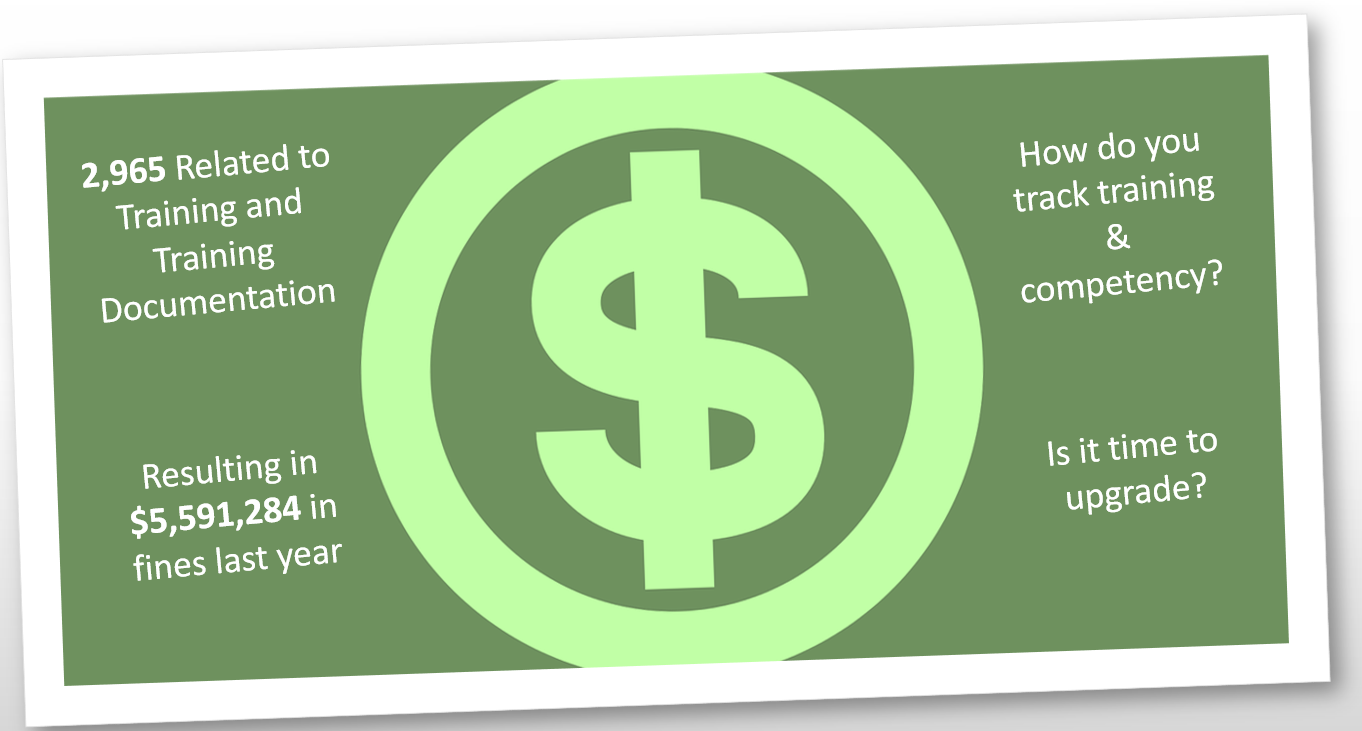

Employee Responsibilities: Employees are expected to take an active role with the training and ask questions as they arise. They are also expected to ensure that they do not perform task that they have not been trained or is outside there scope of work. Contact STAC for assistance if you have any questions! [email protected] http://www.constructionexec.com/article/training-requirements-in-construction Training has become a strong focus recently in the construction industry to reduce accidents and injuries. Studies have proven that training not only provides a more competent workforce, but also a safer work environment. Another motivating factor is fines from the result of OSHA citations. In the 2017 top 10 list, 4,174 of the citations were training related. If those were all compiled into one standard, it would have been the 3rd most frequently cited standard in 2017. But, when is training required? When is refresher training required? What documentation is needed? What resources are available? When is Training Most people are familiar with, and already have training programs for, aerial lifts, rigging & signaling, and powered industrial trucks. But, just to name a few others, hand & power tools, stairways and ladders, occupational noise exposure, fire protection, and employee emergency action plans also require a written training program. What about earth moving equipment, golf carts, and other equipment with no direct OSHA standard? 1926.20(b)(4) states that “the employer shall permit only those employees qualified by training or experience to operate equipment and machinery.” This proof of competency is accomplished through the creation of a written training program. The focus of this program is the recognition and avoidance of hazards and unsafe conditions related to the task. Elements needed in the program include the type of instruction, practical training, and evaluation methods used. Each employee that could be assigned that task or exposed to that hazard must be trained, if not that could be considered a separate violation. It is the responsibility of the employer to document and prove competency. Depending on the type of training, toolbox talks can also be used. When is Refresher Training Required Refresher training can be broken down into three categories: OSHA driven, accident/injury driven, and company driven. The following OSHA standards require annual training refreshers: bloodborne pathogens, confined space rescue team, hazardous waste operations and emergency response (HAZWOPER), occupational noise exposure, and respiratory protection. Toxic and hazardous chemicals all require at least initial training; the following hazardous chemicals require annual training: acrylonitrile, asbestos, benzene, butadiene, cadmium, carcinogens, coke oven emissions, ethylene oxide, formaldehyde, inorganic arsenic, lead, methylenedianiline, & vinyl chloride. First Aid/CPR requires refresher training every 2 years. Process safety management and powered industrial trucks require refresher training every 3 years. Aerial lift refresher should occur every 4 years. Refresher training can also be required in the event of an accident, injury, or near miss. This category includes: when an operator of a vehicle or equipment is observed using it in an unsafe manner, the operator has received an evaluation that reveals the operator is not operating safely, the operator is assigned a different vehicle or equipment, or as workplace conditions change that affect safe operation of the vehicle or equipment. Finally, the company has the ability to implement their own refresher training dates, as long as they minimally meet the OSHA standards. Training Documentation Required The documentation needed for training varies for each standard. But, at a minimum the following information is required. (1) Name and signature of the trainer; (2) Name of the employee (signature is not required); (3) Date of training; (4) Subject of training; (5) Proof of competency and date of evaluation. This proof of competency can be a written test, practical evaluation sheet, or a combination of both. Another critical piece of documentation is the availability of the records. The employer is required to make the training records available to employees and upon request to the Assistant Secretary and the Director for examination and copying. These training documents must be produced within 4 hours of being requested. The storage of records should be maintained for a minimum of 3 years after the date of training. Only the most current training records need to be stored. Failure to document employee safety training can lead to OSHA citations and fines in the event of an OSHA inspection or in an accident investigation. Resources Available Training resource information can also be broken into 4 categories: manufacturer, Insurance agencies, suppliers/dealers, and regulatory agencies. Manufacturers’ create manuals and other safety information that explains safe operating standards and training requirements for the equipment or machinery. OSHA relies on these manuals in the absence of written standards when writing citations. Insurance agencies can provide written training programs and even training in some cases. Equipment and tool dealers also can provide written programs and competent person training. Regulatory agencies, such as OSHA or ANSI, produces a multitude of great resources and publications. The best resources for OSHA training requirements is OSHA 2254 publication “Training Requirements in OSHA Standards.” This publication is the compilation of all OSHA standards in general industry, maritime, construction, agriculture, and federal employee programs that have training requirements. Reposted from constructionexec.com, May 18, 2018, a publication of Associated Builders and Contractors. Copyright 2018. All rights reserved. http://www.constructionexec.com/article/training-requirements-in-construction $5,591,284 from 2,965 OSHA citations for lack of training or training documentation. Contact STAC to ensure peace of mind and prevent an OSHA citation!

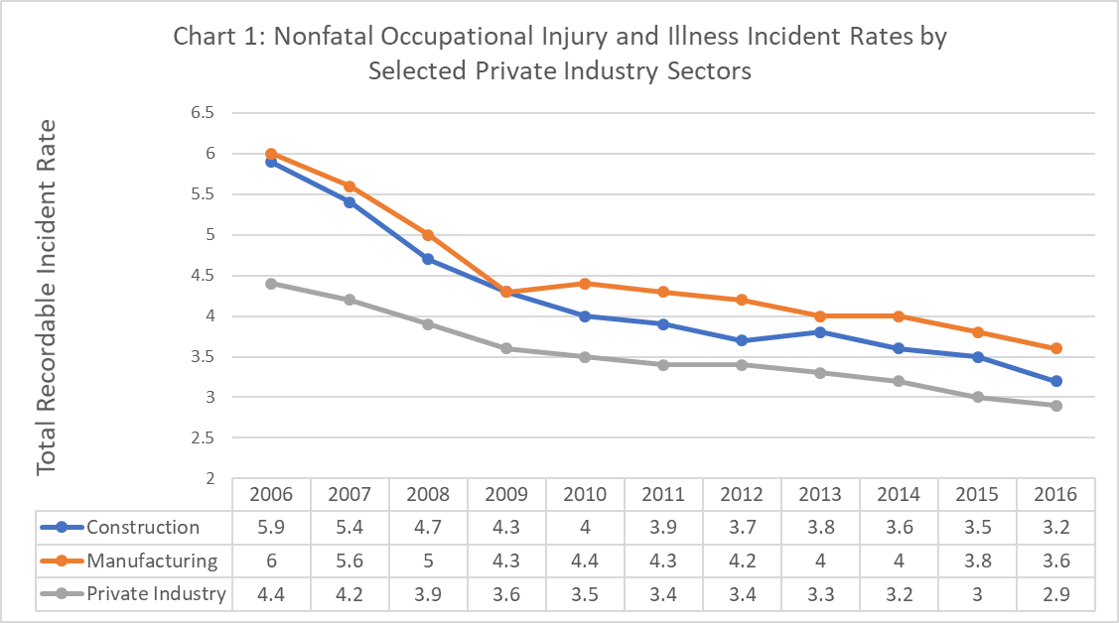

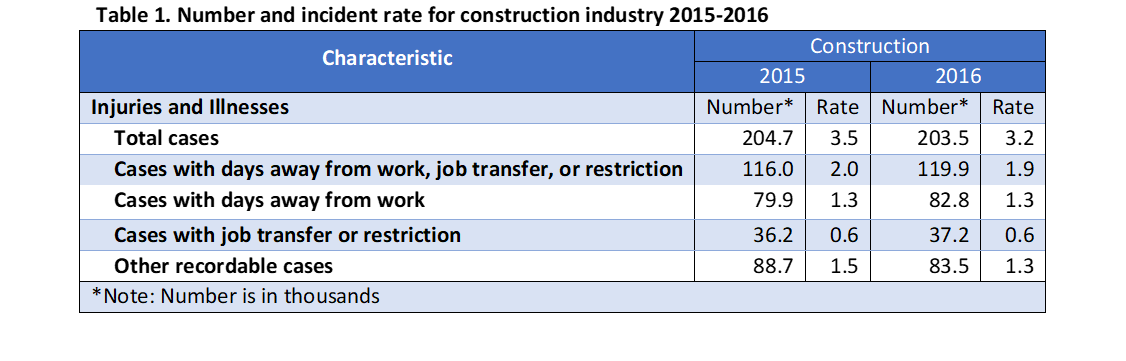

As a core value of business, both in construction and other industries, most will rank safety as a top priority. In construction, many top contractors have accepted and implemented safety oriented cultures and programs to promote going home in the same way they came to work. STAC Enterprises is producing this report because we too believe safety should be a top priority for every business. By partnership in every safety culture, whether it be an industry association or individual companies, we look to set and improve the standard on safety accountability. In this report, information from the latest U.S. Bureau of Labor Statistics will be displayed and discussed to allow other contractors to use as a baseline to benchmark against. By making this information readily available and palatable on a local level, we can start the conversation to assist companies in a benchmarking process and improve awareness in the local area. Beginning on a national level, the report will then focus primarily on the Ohio, Kentucky, and Indiana “Tri-State” area. We want this report to be a conversation starter while encouraging our local industry associations to start benchmarking with one another and begin sharing as an industry how we bring these numbers down in the local area. As the information provided from the 2016 and previous years releases is primarily lagging indicators, the complete picture cannot be grasped without the help of additional contractor input. In future releases, the goal is to also obtain and reveal best practices from local contractors for other industry partners to emulate. Through collaboration and technology we can improve our local area by improving business practices and improving people’s lives. National OutlookNonfatal Information: In the latest Survey of Occupational Injuries and Illnesses, the private industry sector had an all-time low in the number of reported nonfatal workplace injuries and illnesses. Companies in 2016 reported nearly 48,500 fewer nonfatal injury and illness cases in 2016 than the previous year. This decline has been a continued pattern for over a decade. The construction industry also experienced an all-time reported low in incident rates per 100 full-time equivalent (FTE) workers. Below in Chart 1 the overall private industry is compared with construction and manufacturing over the last decade. Although the total number of reported incidents were lower, the number of more serious occupational injuries and illness was slightly higher as the days away from work was essentially unchanged from 2015. In regards to construction, there were roughly 1,200 fewer reported occupational injuries, although the number of incidents with days away from work, job transfer, or restriction increased by roughly 3,000 from 2015 as seen in Table 1. The overall incident rates for both characteristics of incidents, days away from work, job transfer, or restriction and other recordable cases are both down for the year 0.1 and 0.2 respectively. The question comes to mind, have we really gotten better, or just better at reporting? General contractors in an effort to reduce incident rates and improve response time are putting EMS professionals on site, which provides better first aid care to the individuals, yet essentially removes the smaller first aid reporting which would sometimes show on a OSHA Log. Likewise, employers have begun to seek more knowledgeable healthcare facilities which would choose to use first aid measures that are not recordable versus those which would have traditionally used stitches, or prescribed some type of medication or ointment. Does this explain the full picture or is there more for the story to tell? Seen as forward progress due to the lower incident rate, one would believe that the overall industry would be getting much safer although the next set of statistics may point in the opposing direction.

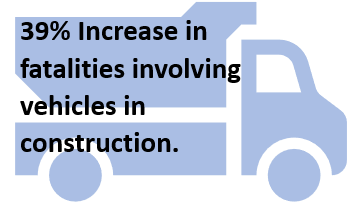

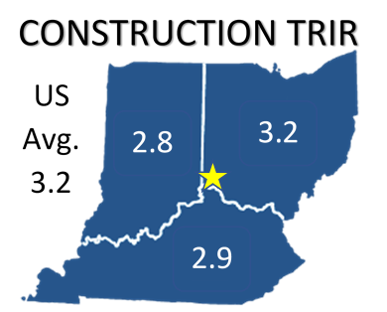

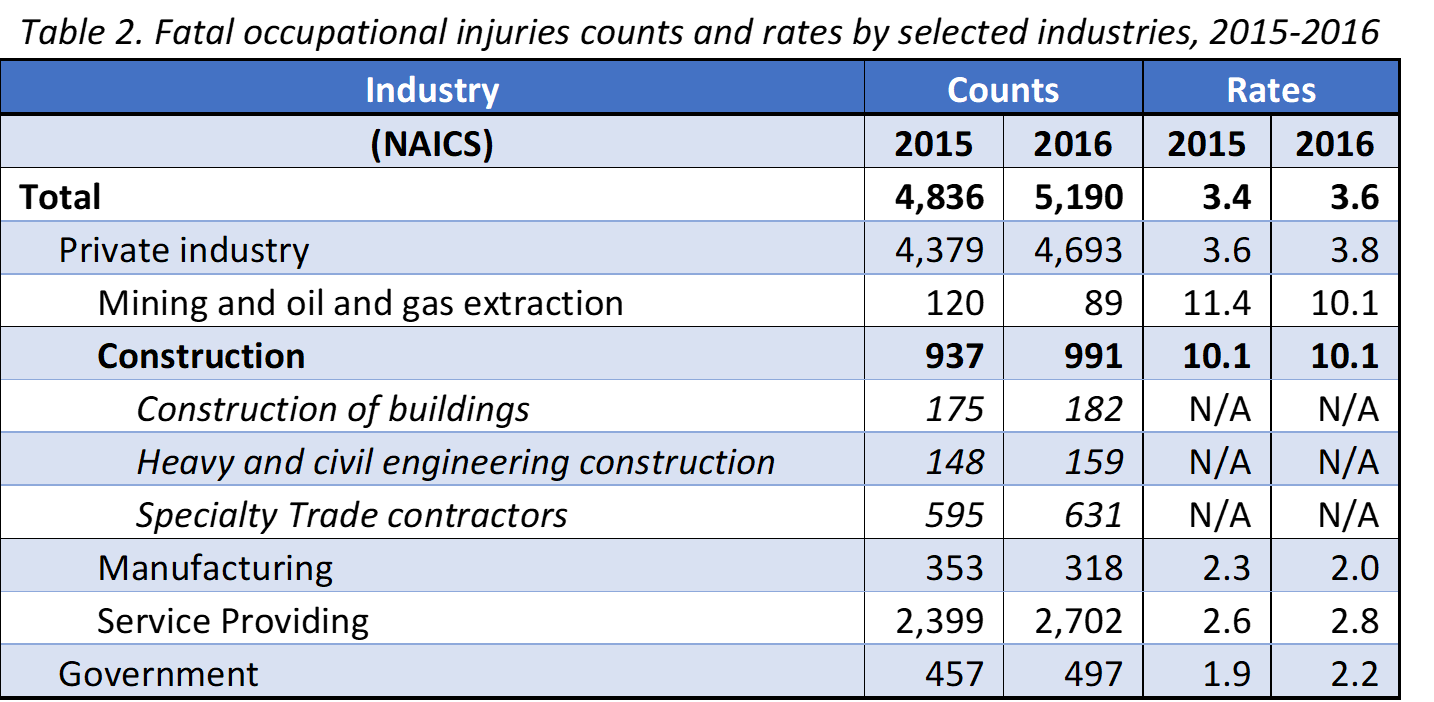

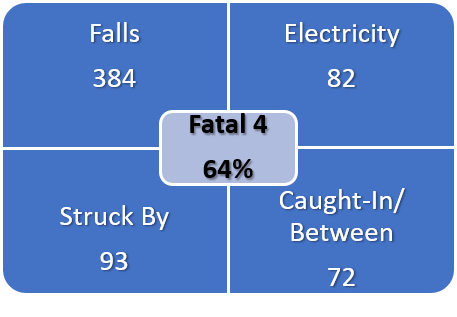

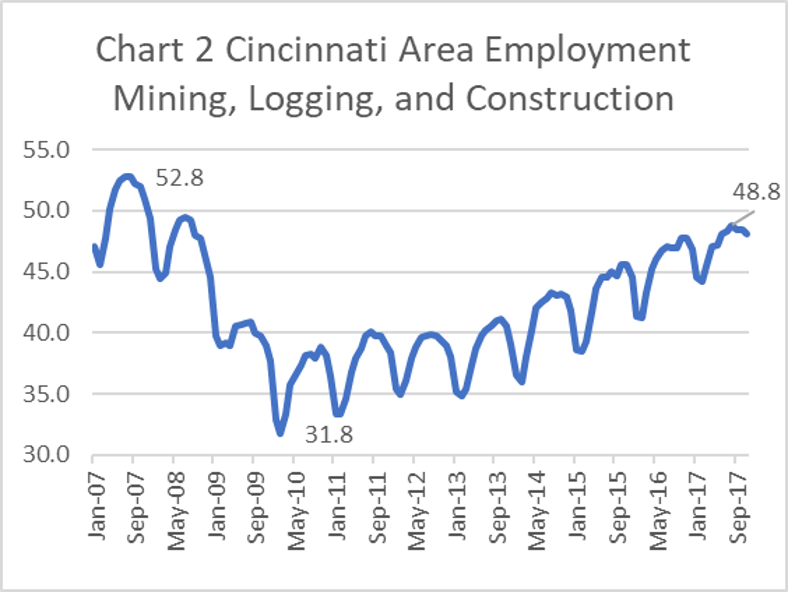

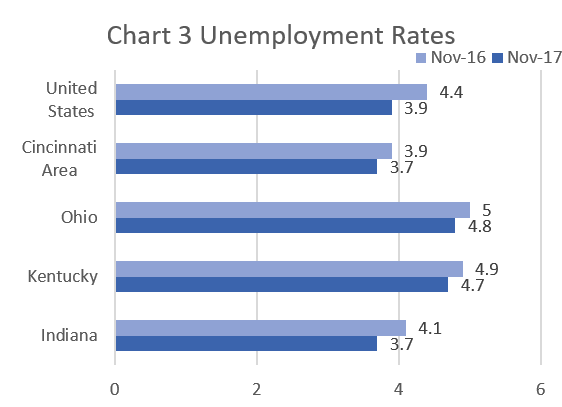

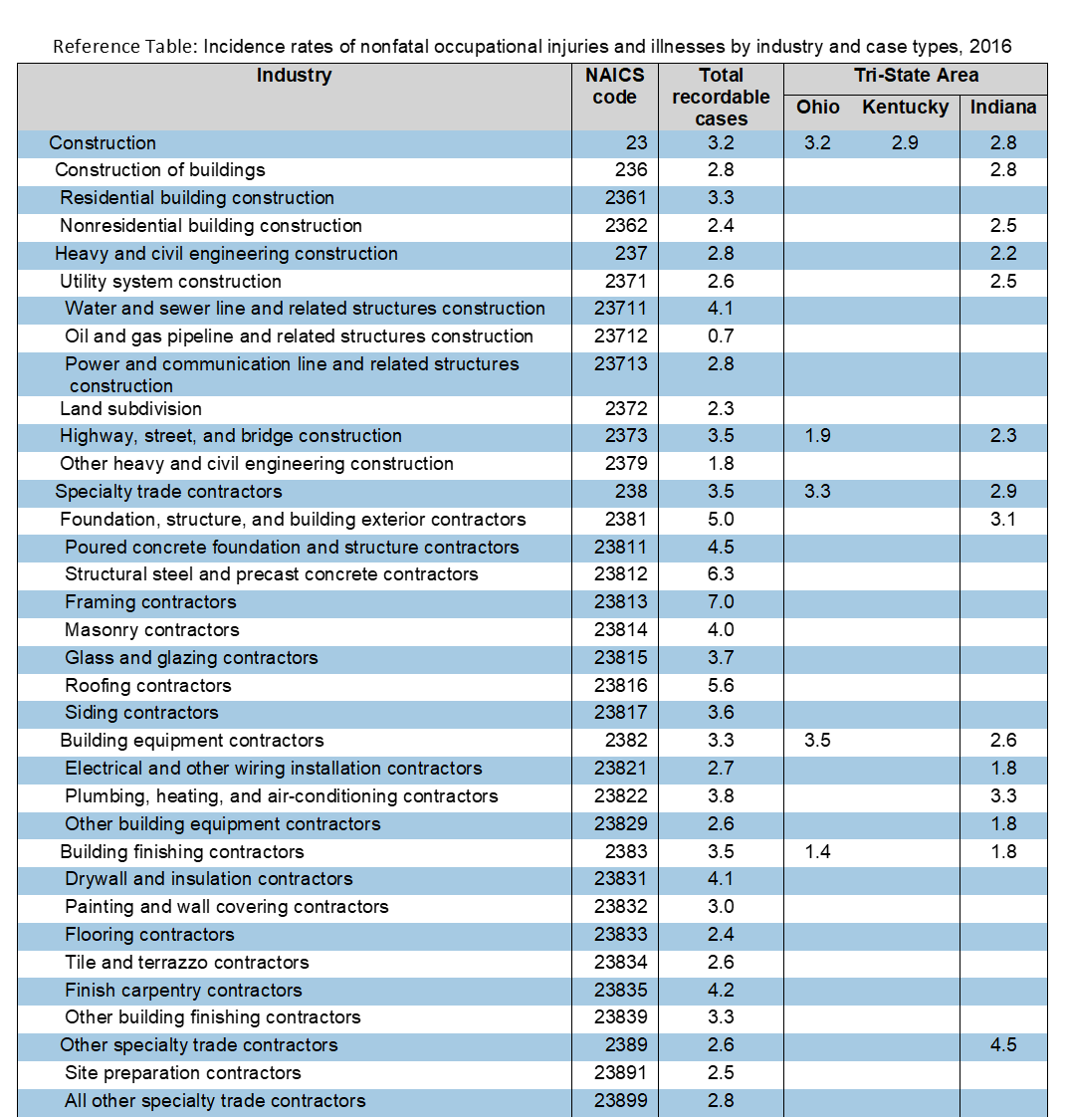

With an industry in need of skilled workers, those that would traditionally retire have continued to stay and work while the industry continues to recruit. Unfortunately, 2016 reported an increase in fatalities of construction workers over the age of 55. Vehicular accidents also increased by 39% for the construction industry meaning workers are increasingly being impacted on their commute to projects. This information may have also been the reason first line supervisors had the highest fatality count since 2003. The fatal four; falls, struck by, caught in between and electrocution once again claimed the most lives in 2016 for construction with nearly 2/3 of all fatalities. Occupations such as roofers and structural steel ironworkers experienced death counts of 101 and 16 respectively, both the highest counts since 2003 for each occupation. Lastly an increase in workplace violence contributed to such historically high rates in this decade. Although the fatality rates have remained the same for the industry as a whole, the loss of nearly 1,000 construction workers in a year is unacceptable and must be decreased. What can we do to decrease these numbers? Is it training and education, is it better equipment or tools, or is it culture that needs improved? Reports from Dodge Data and Analytics, as well as the Associated Builders and Contractors indicate that a strong safety program lead by upper management and shown by example have a strong correlation with reduced injuries and incident rates for contractors. Has your organization truly adopted the practices in which they claim to take to heart or is it another box to check for an owner, general contractor or compliance agency? How is this attitude locally? Tri-State Outlook (Ohio, Kentucky, and Indiana)Employment Information: The common theme of the Tri-State area is simple – as an industry we can’t find enough people to do more work. Seems like everyone is busier than a one armed wallpaper hanger. This information is reflected in the most recent employment and unemployment rates for the Cincinnati Area. Currently the construction industry employment in the Tri-State region is near the highs of 2008 at the beginning of the Great Recession shown in Chart 2. Employment for the construction industry has been on a steady climb from its lowest depression in 2010. This information also closely corresponds with the regional unemployment rate below the national average and the regional statewide averages. As seen in Chart 3, the Cincinnati Area unemployment rate dropped 5% or 0.2 from November 2016 to November 2017, less than the national average of 11%. With such an increase in work and employment, is the safety related information keeping in line with national standards?  Safety Statistics: The three states, Ohio, Kentucky, and Indiana, within the tri-state region, all are at or below the national average for construction when it comes to total recordable cases (TRIR). The OSHA Recordable Incident Rate (or Incident Rate) is calculated by multiplying the number of recordable cases by 200,000, and then dividing that number by the number of labor hours at the company. Ohio, with the worst of the three states, matches the national average of 3.2. Kentucky, then Indiana come next in line with 2.9 and 2.8 respectively. Indiana also has the best average for specialty trade contractors at 2.9 which is below the national average of 3.5 Shown in the Reference Table below, one can see most of the individual trades or other sub-sectors of the industry are not reported on a state by state basis. Ohio though, has the best in the tri-state for highway construction and finishing contractors with rates of 1.9 and 1.4 which are well below the national average of 3.5 in both of those selected industries. Local contractors and industry association safety initiatives may be assisting the efforts to reduce overall incidents and safety indicators on local projects. Service in your local area, transparency between contractors, accountability within your organization and collaboration with local and regional trade associations is key for a strong safety culture. Take these statistics to heart and promote safe work practices today. As an industry we must remove our incidents, fatalities and the mindset that safety is not a top priority!

I’m sure that you are aware of the OSHA Act of 1970: General Duty Clause 5(a)where it states the employer requirement, but are you aware of Section 5(b)?

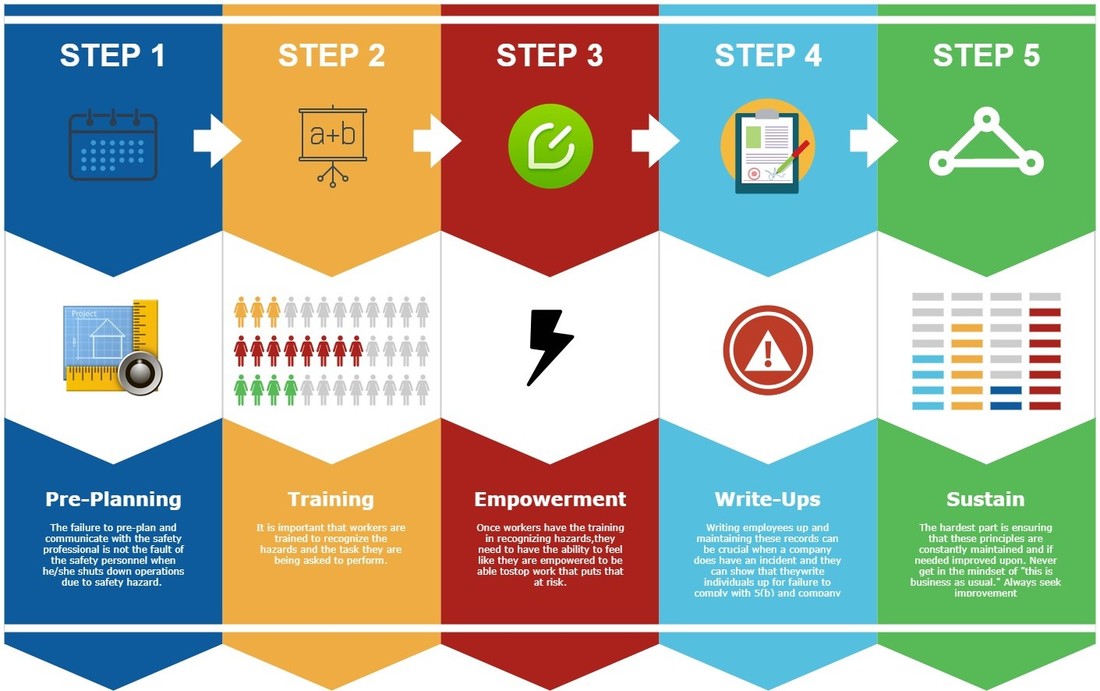

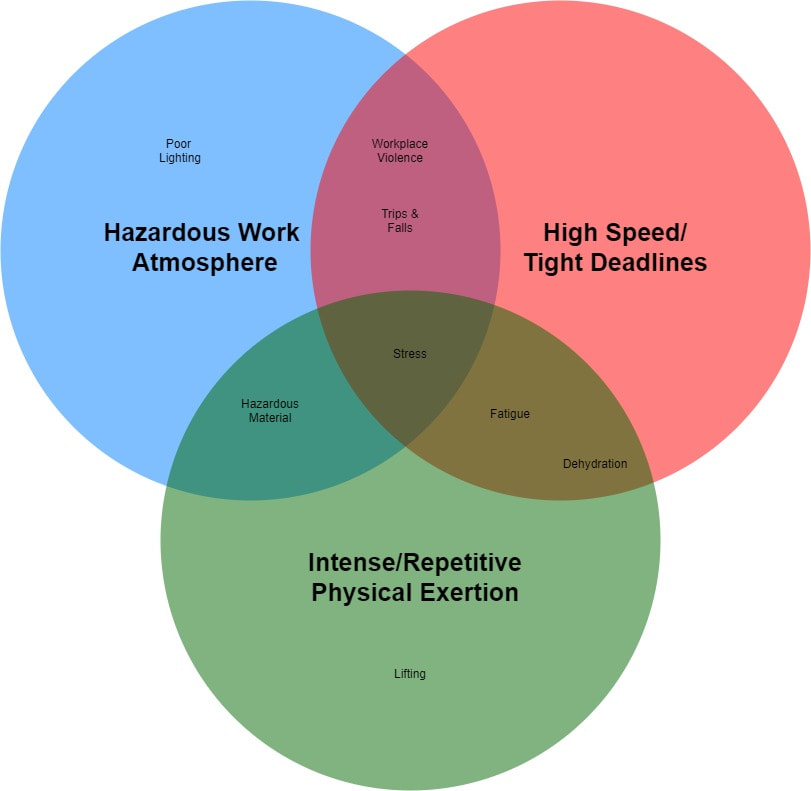

(a) Each employer - (1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees; (2) shall comply with occupational safety and health standards promulgated under this Act. (b) Each employee shall comply with occupational safety and health standards and all rules, regulations, and orders issued pursuant to this Act which are applicable to his own actions and conduct. What is sometimes lost in the world of safety is section 5(b) of the general duty clause and we only focus on 5(a). Partially the reason is that OSHA is going to cite the company, not the employee for working in an environment where a hazard occurs. But, if the employee knowingly put himself or herself at risk and violates company and OSHA policies, the company might not be cited. For instance, a recent case in Florida saw the judge vacate a general duty cause citation after an employee was struck by a reversing bulldozer. The reasoning—the Department of Labor representatives failed to establish that any of the workers were exposed to the struck by hazard, according to the Judge. Meaning, the employee knowingly put himself at risk against company polices. Cases like this show that 5(b) was intended to protect the company in cases where employees knowingly put themselves at risk, failure to follow their company training on hazards, and OSHA standards. So, what does this mean? Employers need to ensure they are giving the proper tools to their employees to spot these hazards. These tools include: 1)Pre-Planning, Pre-Planning, & more Pre-Planning: The failure to pre-plan and communicate with the safety professional is not the fault of the safety personnel when he/she shuts down operations due to safety hazard. 2)Training: It is important that workers are trained to recognize the hazards and the task they are being asked to perform. 3)Empowerment: Once workers have the training in recognizing hazards, they need to have the ability to feel like they are empowered to be able to stop work that puts that at risk. 4)Write-Ups: The dreaded write-ups, the hardest thing to do. It is important that safety professionals write-up employees that choose to take risk, without being asked, and create a hazardous work environment. Writing employees up and maintaining these records can be crucial when a company does have an incident and they can show that they write individuals up for failure to comply with 5(b) and company policies. 5)Sustain: The hardest part is ensuring that these principles are constantly maintained and if needed improved upon. Never get in the mindset of this is business as usual. The training tracking piece with then STAC system has the capability to allow for these tools to be put into action. A major piece in pre-planning is quickly knowing which employees are trained for what task and what further training that employees might need. Additionally, when each employee receives their own STAC card it is a representation of how serious the company takes safety and empowers them to know what training they have and when it expires. Thoughts: So, what are your thoughts on 5(b)? Have you ever heard of it? What is the current policy that you use to ensure employees are compliant with this law? OSHA Act of 1970: General Duty Clause (a) Each employer -- (1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees; I’m sure that any safety professional can recite the General Duty Clause just like reciting the chorus from Don’t Stop Believing from the band Journey (a song that my wife tragically banned from our wedding). But, how often have we seen or worked in places with hazards and not reported or corrected the issue? A study by the Rand Corporation produced startling facts about the American workplace. One-half of American workers reported exposure to unpleasant and potentially hazardous working conditions. I will repeat it again, 50% of American workers work in an environment that is likely to cause physical harm or death. 66% reported working at high speeds or under tight deadlines with one-fourth stating they have too little time to do their jobs. And nearly 75% of American reported that their work included intense or repetitive physical exertion on the job. These findings fit perfectly into the Bureau of Labor and Statistics on the 8 common workplace injuries: Lifting, fatigue, dehydration, poor lighting, hazardous material, workplace violence, trips and falls, and stress. Each of these common workplace injuries fit at least into at least one of the categories of hazardous work conditions, working at high speeds (rushing), and intense or repetitive physical exertion. So, don’t stop believing, just because it’s a small-town girl or city boy doesn’t mean they should have to work in a hazardous work condition. We need to ensure that we are identifying and creating solutions to workplace hazards.

What have you found is the most effective in prevention or correcting workplace hazards? Do these statistics startle you? Or is that what you see in the workplace? |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed