|

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background: Power Tools include: Electric, pneumatic, liquid fuel, power-actuated, and hydraulic power tools. Employees who use power tools and are exposed to the hazards of falling, flying, abrasive, and splashing objects, or to harmful dusts, fumes, mists, vapors, or gases must be provided with the appropriate personal protective equipment. Employees should be trained in the proper use of all tools. Workers should be able to recognize the hazards associated with the different types of tools and the safety precautions necessary. Five basic safety rules can help prevent hazards associated with the use of hand and power tools: Power tools must be fitted with guards and safety switches; they are extremely hazardous when used improperly. The types of power tools are determined by their power source: electric, pneumatic, liquid fuel, hydraulic, and powder-actuated. To prevent hazards associated with the use of power tools, workers should observe the following general precautions:

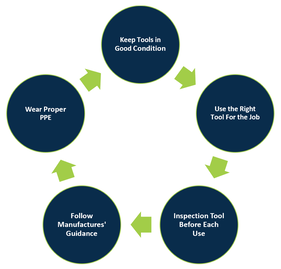

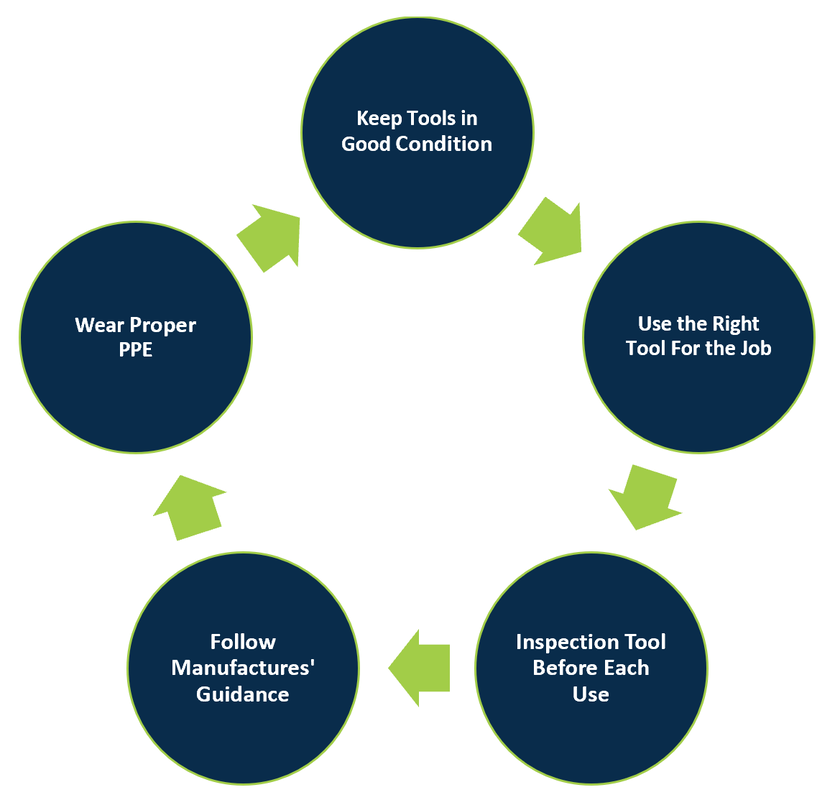

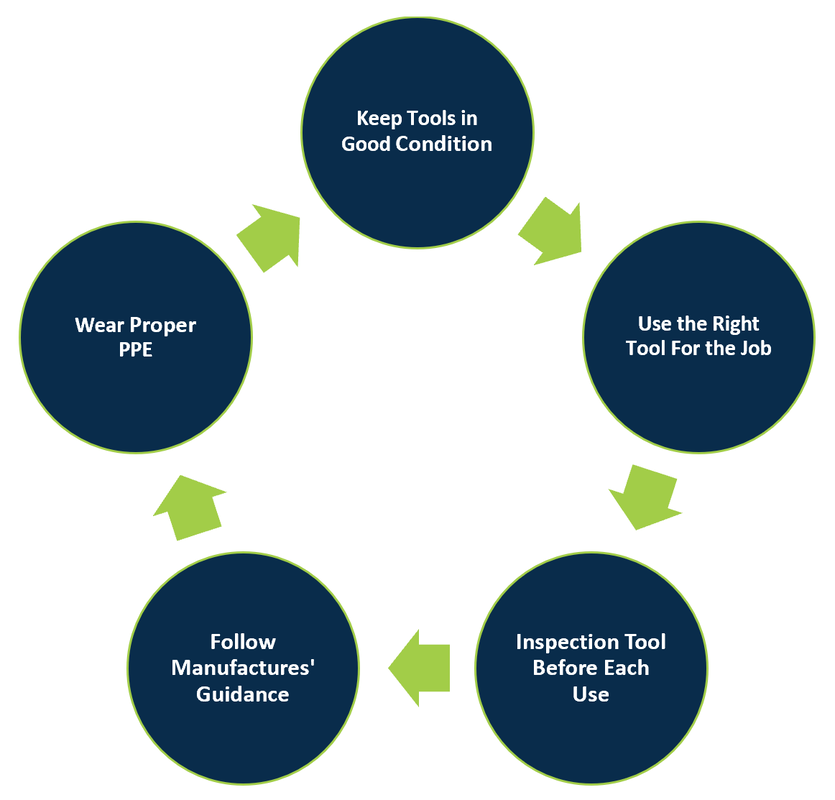

Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Knives and scissors must be sharp; dull tools can cause more hazards than sharp ones. Cracked saw blades must be removed from service. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE.

0 Comments

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Five basic safety rules can help prevent hazards associated with the use of tools: Pneumatic Tools: Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders.

There are several dangers associated with the use of pneumatic tools. First and foremost is the danger of getting hit by one of the tool’s attachments or by some kind of fastener the worker is using with the tool. Pneumatic tools must be checked to see that the tools are fastened securely to the air hose to prevent them from becoming disconnected. A short wire or positive locking device attaching the air hose to the tool must also be used and will serve as an added safeguard. If an air hose is more than 1 /2-inch (12.7 millimeters) in diameter, a safety excess flow valve must be installed at the source of the air supply to reduce pressure in case of hose failure. In general, the same precautions should be taken with an air hose that are recommended for electric cords, because the hose is subject to the same kind of damage or accidental striking, and because it also presents tripping hazards. When using pneumatic tools, a safety clip or retainer must be installed to prevent attachments such as chisels on a chipping hammer from being ejected during tool operation. Pneumatic tools that shoot nails, rivets, staples, or similar fasteners and operate at pressures more than 100 pounds per square inch (6,890 kPa), must be equipped with a special device to keep fasteners from being ejected, unless the muzzle is pressed against the work surface. Airless spray guns that atomize paints and fluids at pressures of 1,000 pounds or more per square inch (6,890 kPa) must be equipped with automatic or visible manual safety devices that will prevent pulling the trigger until the safety device is manually released. Eye protection is required, and head and face protection is recommended for employees working with pneumatic tools. Screens must also be set up to protect nearby workers from being struck by flying fragments around chippers, riveting guns, staplers, or air drills. Compressed air guns should never be pointed toward anyone. Workers should never “dead-end” them against themselves or anyone else. A chip guard must be used when compressed air is used for cleaning. Use of heavy jackhammers can cause fatigue and strains. Heavy rubber grips reduce these effects by providing a secure handhold. Workers operating a jackhammer must wear safety glasses and safety shoes that protect them against injury if the jackhammer slips or falls. A face shield also should be used. Noise is another hazard associated with pneumatic tools. Working with noisy tools requires proper hearing protection. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Masonry saws are used to cut tiles, bricks, and blocks of stone, concrete, and other materials. Concrete saws are used to cut channels or openings through concrete blocks, slabs, and walls. Both types of saws can be hand-held, mounted on a stand, or wheeled by hand or motor and may be powered by electricity, compressed air, or fuel. Working with saws can expose workers to hazards such as cutting blades, kick-back, push-back, and pull-ins; training and proper work practices are the key to safety.

Workers require training on the safe use of masonry and concrete saws. Cutting blades should be the correct size, installed properly, guarded at all times, and speed should not exceed the manufacturer’s suggested RPM. Workers should use the correct blade for the job and inspect it for defects before each use. Saws should be maintained and kept clean from dust build-up. Workers using concrete and masonry saws should always ensure that there are no gas or electric utility lines embedded within their cutting zones. Saws pose kick-back, push-back and pull-in dangers if they cannot run freely through the cutting material. Blades are designed to go in a straight line; crooked or off-line cuts can cause blades to pinch or bite into the material and jam. Though a blade may be jammed, the running motor builds up power and can cause a worker to lose control of the saw and become exposed to the cutting blade. Loss of control includes kick-back where the saw thrusts up and backward, pushback where the saw thrusts straight back, and pull-in where the saw pulls the worker in toward the blade. Hand-held saws pose special dangers if kick-back occurs because the worker can lose control and drop the saw. Hand-helds should never be used over shoulder height or on ladders and stepstools. Saw push-back at a height could cause a worker to fall. If elevated cutting work is required, the saw should be mounted on guide tracks for the job. Walls and bricks that are cut should be supported so they do not fall and pinch the blade or crush workers. Mounted saws should be kept on firm, flat surfaces for stability. Workers should keep their hands clear of the cutting blade while holding materials firmly against the backstop. Conveyor surfaces should be free of debris that could cause products to slip and pinch the blade. Longer materials should be supported by scaffolds to prevent blade pinching. Walk-behind saws keep the worker more removed from the cutting blade. These saws should be guided in a straight line with several passes for each cut. Workers should not push against the saw; this could cause the blade to jump or climb out of the cutting path and the operator could lose control. Personal protective equipment (PPE) for masonry and concrete saws varies depending on the job task, but may include hard hats, boots, safety glasses and face shields, hearing protection, gloves, and respiratory protection from hazardous dusts The dust created by concrete and masonry saws can be a serious health hazard. The materials that are cut typically contain silica. Repeatedly breathing too much silica dust can eventually lead to silicosis, a disabling and irreversible lung disease; it can also cause lung cancer. The dust can be a hazard not only to the saw operator, but also to others working in the area. To limit exposures, control dust with a water spray directed at the cutting area. Alternatively, local exhaust ventilation, with a hood attached directly to the saw, can capture most of the dust generated. The saw may come with the appropriate attachments for water or exhaust ventilation, or it may need some retrofitting. If these control methods are not possible, respirators can provide adequate protection, but only if selected and used properly. Even with control measures in place, workers may still need to wear respirators. For more guidance, consult with an industrial hygienist or other safety and health professional. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Hand tools are tools that are powered manually. Hand tools include anything from axes to wrenches. The greatest hazards posed by hand tools result from misuse and improper maintenance. Employees who use hand and power tools and are exposed to the hazards of falling, flying, abrasive, and splashing objects, or to harmful dusts, fumes, mists, vapors, or gases must be provided with the appropriate personal protective equipment. Employees should be trained in the proper use of all tools. Workers should be able to recognize the hazards associated with the different types of tools and the safety precautions necessary. Five basic safety rules can help prevent hazards associated with the use of hand and power tools: General Safety:

Wrenches must not be used when jaws are sprung to the point that slippage occurs. Impact tools such as drift pins, wedges, and chisels must be kept free of mushroomed heads. The wooden handles of tools must not be splintered. Iron or steel hand tools may produce sparks that can be an ignition source around flammable substances. Where this hazard exists, spark-resistant tools made of non-ferrous materials should be used where flammable gases, highly volatile liquids, and other explosive substances are stored or used. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Knives and scissors must be sharp; dull tools can cause more hazards than sharp ones. Cracked saw blades must be removed from service. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background:

Employees using electric tools must be aware of several dangers. Among the most serious hazards are electrical burns and shocks. Electrical shocks, which can lead to injuries such as heart failure and burns, are among the major hazards associated with electric powered tools. Under certain conditions, even a small amount of electric current can result in fibrillation of the heart and death. An electric shock also can cause the user to fall off a ladder or other elevated work surface and be injured due to the fall. To protect the user from shock and burns, electric tools must have a three-wire cord with a ground and be plugged into a grounded receptacle, be double insulated, or be powered by a low-voltage isolation transformer. Three-wire cords contain two current carrying conductors and a grounding conductor. Any time an adapter is used to accommodate a two-hole receptacle, the adapter wire must be attached to a known ground. The third prong must never be removed from the plug. Double-insulated tools are available that provide protection against electrical shock without third-wire grounding. On double-insulated tools, an internal layer of protective insulation completely isolates the external housing of the tool. Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Employee Requirements: To prevent hazards associated with the use of power tools, workers should observe the following general precautions:

Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner Portable Abrasive Tools:

Portable abrasive grinding, cutting, polishing, and wire buffing wheels create special safety problems because they may throw off flying fragments. Abrasive wheel tools must be equipped with guards that: 1) cover the spindle end, nut, and flange projections; (2) maintain proper alignment with the wheel; and (3) do not exceed the strength of the fastenings. Before an abrasive wheel is mounted, it must be inspected closely for damage and should be sound- or ring-tested to ensure that it is free from cracks or defects. To test, wheels should be tapped gently with a light, non-metallic instrument. If the wheels sound cracked or dead, they must not be used because they could fly apart in operation. A stable and undamaged wheel, when tapped, will give a clear metallic tone or “ring.” To prevent an abrasive wheel from cracking, it must fit freely on the spindle. The spindle nut must be tightened enough to hold the wheel in place without distorting the flange. Always follow the manufacturer’s recommendations. Take care to ensure that the spindle speed of the machine will not exceed the maximum operating speed marked on the wheel. An abrasive wheel may disintegrate or explode during start-up. Allow the tool to come up to operating speed prior to grinding or cutting. The employee should never stand in the plane of rotation of the wheel as it accelerates to full operating speed. Portable grinding tools need to be equipped with safety guards to protect workers not only from the moving wheel surface, but also from flying fragments in case of wheel breakage. When using a powered grinder: Always use eye or face protection; Turn off the power when not in use; & Never clamp a hand-held grinder in a vise Guards: The exposed moving parts of power tools need to be safeguarded. Belts, gears, shafts, pulleys, sprockets, spindles, drums, flywheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded. Machine guards, as appropriate, must be provided to protect the operator and others from the following: Point of operation, In-running nip points., Rotating parts, & Flying chips and sparks Safety guards must never be removed when a tool is being used. Portable circular saws having a blade greater than 2 inches (5.08 centimeters) in diameter must be equipped at all times with guards. An upper guard must cover the entire blade of the saw. A retractable lower guard must cover the teeth of the saw, except where it makes contact with the work material. The lower guard must automatically return to the covering position when the tool is withdrawn. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE. OSHA Standard: 1910.134 Training Frequency: Upon initial assignment (before mask is worn), and annually. Training Style: Hands-on When is Respiratory Protection Required? - In any workplace where respirators are necessary to protect the health of the employee or whenever respirators are required by the employer Background: Respiratory Protection Program: Respiratory protection program requires the employer to develop and implement a written respiratory protection program with required worksite-specific procedures and elements for required respirator use. The program must be administered by a suitably trained program administrator. In addition, certain program elements may be required for voluntary use to prevent potential hazards associated with the use of the respirator. The program shall be updated as necessary to reflect those changes in workplace conditions that affect respirator use. The employer shall include in the program the following provisions:

The employer shall provide respirators, training, and medical evaluations at no cost to the employee. Training Information: The training must be comprehensive, understandable, and recur annually, and more often if necessary. The employer shall ensure that each employee can demonstrate knowledge of at least the following:

Retraining: Retraining shall be administered annually, and when the following situations occur:

OSHA Standard: 1926.102

Training: Initially Upon assignment and as conditions or equipment changes The employer shall train each affected employee:

Protectors shall meet the following minimum requirements:

Eye and face protection equipment required by this Part shall meet the requirements specified in American National Standards Institute, Z87.1-1968, Practice for Occupational and Educational Eye and Face Protection. OSHA Standard: 1926.64

Training Requirement: Initial training is required for each employee involved in operating a process of highly hazardous chemicals BEFORE being involved in that operation. Refresher training shall be provided at least every three years, and more often if necessary. Training Documentation: The employer shall prepare a record which contains the identity of the employee, the date of training, and the means used to verify that the employee understood the training. Training: All employees, including maintenance and contractor employees, involved with highly hazardous chemicals need to fully understand the safety and health hazards of the chemicals and processes they work with for the protection of themselves and others. The operating procedures are often viewed as the standard operating practices (SOPs) for operations. Control room personnel and operating staff, in general, need to have a full understanding of operating procedures. Training in subjects such as operating procedures and safety work practices, emergency evacuation and response, safety procedures, routine and nonroutine work authorization activities, and other areas pertinent to process safety and health will need to be covered by an employer’s training program. Because of this this, hands-on-training is strongly encouraged to be used. Training evaluations are strongly encouraged. If, after the evaluation, it appears that the trained employees are not at the level of knowledge and skill that was expected, the employer will need to revise the training program, provide retraining, or provide more frequent refresher training sessions until the deficiency is resolved. Audits: Employers need to select a trained individual or assemble a trained team of people to audit the process safety management system and program. The audit is to include an evaluation of the design and effectiveness of the process safety management system and a field inspection of the safety and health conditions and practices to verify that the employer’s systems are effectively implemented. Evaluate: Employers need to periodically evaluate their training programs to see if the necessary skills, knowledge, and routines are being properly understood and implemented by their trained employees. Subpart: D – Occupational Health and Environmental Controls

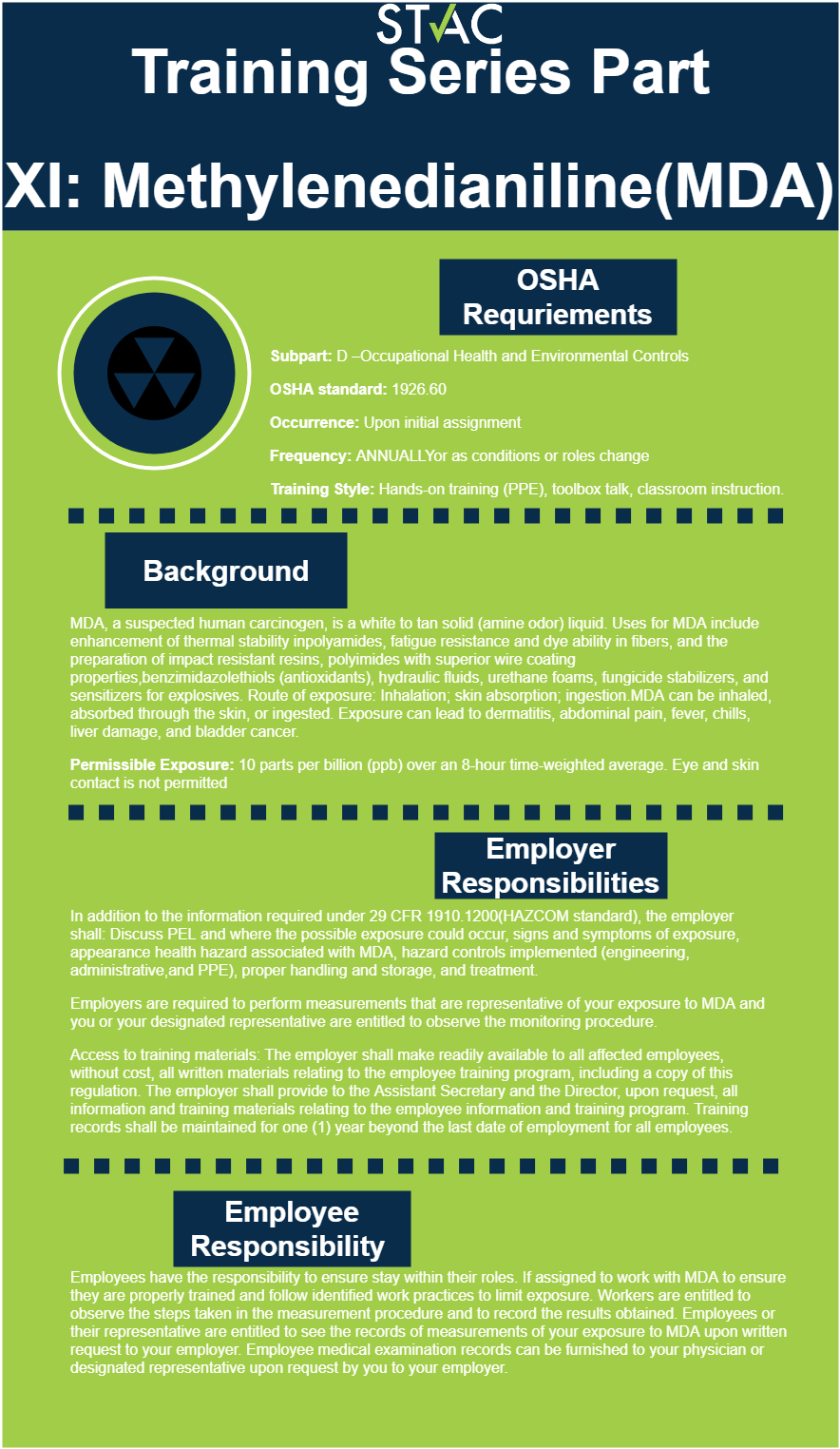

OSHA Standard: 1926.60 Occurrence: Upon initial assignment Frequency: ANNUALLY or as conditions or roles change Training Style: Hands on training (PPE), toolbox talk, classroom instruction. Background: MDA, a suspected human carcinogen, is a white to tan solid (amine odor) liquid. Uses for MDA include enhancement of thermal stability in polyamides, fatigue resistance and dye ability in fibers, and the preparation of impact resistant resins, polyimides with superior wire coating properties, benzimidazolethiols (antioxidants), hydraulic fluids, urethane foams, fungicide stabilizers, and sensitizers for explosives. Route of exposure: Inhalation; skin absorption; ingestion. MDA can be inhaled, absorbed through the skin, or ingested. Exposure can lead to dermatitis, abdominal pain, fever, chills, liver damage, and bladder cancer. Permissible Exposure: 10 parts per billion (ppb) over an 8-hour time weighted average. Eye and skin contact are not permitted Employer Responsibilities: In addition to the information required under 29 CFR 1910.1200 (HAZCOM standard), the employer shall: Discuss PEL and where the possible exposure could occur, signs and symptoms of exposure, appearance health hazard associated with MDA, hazard controls implemented (engineering, administrative, and PPE), proper handling and storage, and treatment. Employers are required to perform measurements that are representative of your exposure to MDA and you or your designated representative are entitled to observe the monitoring procedure. Access to training materials: The employer shall make readily available to all affected employees, without cost, all written materials relating to the employee training program, including a copy of this regulation. The employer shall provide to the Assistant Secretary and the Director, upon request, all information and training materials relating to the employee information and training program. Training records shall be maintained for one (1) year beyond the last date of employment for all employees. Employee Responsibilities: Employees have the responsibility to ensure stay within their roles. If assigned to work with MDA to ensure they are properly trained and follow identified work practices to limit exposure. Workers are entitled to observe the steps taken in the measurement procedure and to record the results obtained. Employees or their representative are entitled to see the records of measurements of your exposure to MDA upon written request to your employer. Employee medical examination records can be furnished to your physician or designated representative upon request by you to your employer. Contact STAC for assistance if you have any questions! [email protected] |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed