|

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner Portable Abrasive Tools:

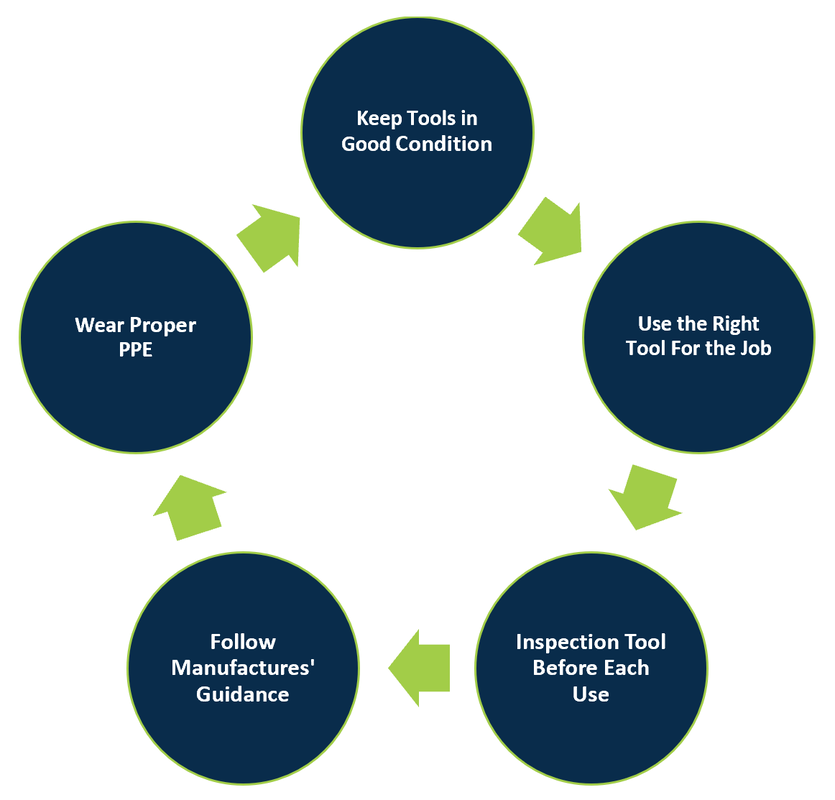

Portable abrasive grinding, cutting, polishing, and wire buffing wheels create special safety problems because they may throw off flying fragments. Abrasive wheel tools must be equipped with guards that: 1) cover the spindle end, nut, and flange projections; (2) maintain proper alignment with the wheel; and (3) do not exceed the strength of the fastenings. Before an abrasive wheel is mounted, it must be inspected closely for damage and should be sound- or ring-tested to ensure that it is free from cracks or defects. To test, wheels should be tapped gently with a light, non-metallic instrument. If the wheels sound cracked or dead, they must not be used because they could fly apart in operation. A stable and undamaged wheel, when tapped, will give a clear metallic tone or “ring.” To prevent an abrasive wheel from cracking, it must fit freely on the spindle. The spindle nut must be tightened enough to hold the wheel in place without distorting the flange. Always follow the manufacturer’s recommendations. Take care to ensure that the spindle speed of the machine will not exceed the maximum operating speed marked on the wheel. An abrasive wheel may disintegrate or explode during start-up. Allow the tool to come up to operating speed prior to grinding or cutting. The employee should never stand in the plane of rotation of the wheel as it accelerates to full operating speed. Portable grinding tools need to be equipped with safety guards to protect workers not only from the moving wheel surface, but also from flying fragments in case of wheel breakage. When using a powered grinder: Always use eye or face protection; Turn off the power when not in use; & Never clamp a hand-held grinder in a vise Guards: The exposed moving parts of power tools need to be safeguarded. Belts, gears, shafts, pulleys, sprockets, spindles, drums, flywheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded. Machine guards, as appropriate, must be provided to protect the operator and others from the following: Point of operation, In-running nip points., Rotating parts, & Flying chips and sparks Safety guards must never be removed when a tool is being used. Portable circular saws having a blade greater than 2 inches (5.08 centimeters) in diameter must be equipped at all times with guards. An upper guard must cover the entire blade of the saw. A retractable lower guard must cover the teeth of the saw, except where it makes contact with the work material. The lower guard must automatically return to the covering position when the tool is withdrawn. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed