|

OSHA Standard: 1926.300 – Subpart I – Tools – Hand & Power Training: Training should be performed upon initial assignment/before use of tool. Frequency: When roles, conditions, or equipment changes. Or when worker is using the equipment in an unsafe manner. Background: Five basic safety rules can help prevent hazards associated with the use of hand and power tools: Fuel-powered tools are usually operated with gasoline. The most serious hazard associated with the use of fuel-powered tools comes from fuel vapors that can burn or explode and also give off dangerous exhaust fumes. The worker must be careful to handle, transport, and store gas or fuel only in approved flammable liquid containers, according to proper procedures for flammable liquids.

Before refilling a fuel-powered tool tank, the user must shut down the engine and allow it to cool to prevent accidental ignition of hazardous vapors. When a fuel-powered tool is used inside a closed area, effective ventilation and/or proper respirators such as atmosphere-supplying respirators must be utilized to avoid breathing carbon monoxide. Fire extinguishers must also be available in the area. To prevent hazards associated with the use of liquid fuel tools, workers should observe the following precautions:

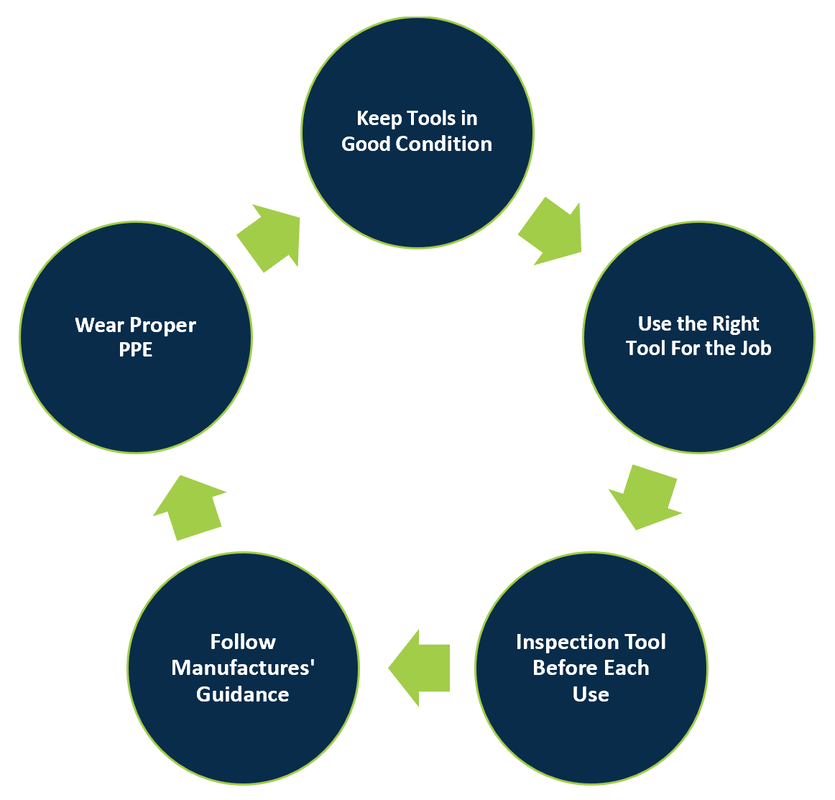

Employer Requirements: The employer is responsible for the safe condition of tools and equipment used by employees. Employers shall not issue or permit the use of unsafe hand tools. Employees should be trained in the proper use and handling of tools and equipment. Appropriate personal protective equipment such as safety goggles and gloves must be worn to protect against hazards that may be encountered while using hand tools. Workplace floors shall be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools. Employee Requirements: Employees, when using saw blades, knives, or other tools, should direct the tools away from aisle areas and away from other employees working in close proximity. Cracked saw blades must be removed from service. Take Home Points: Both employer and employee have responsibility in ensuring safety while operating hand tools. Ensure that the tool is maintained and inspected, use the right tool for the right job, follow manufacturers’ guidelines, ensure the workplace is safe for use of the tool, and wear the appropriate PPE.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorSTAC Admin Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed